135/8 inch BOP Stack ⋆

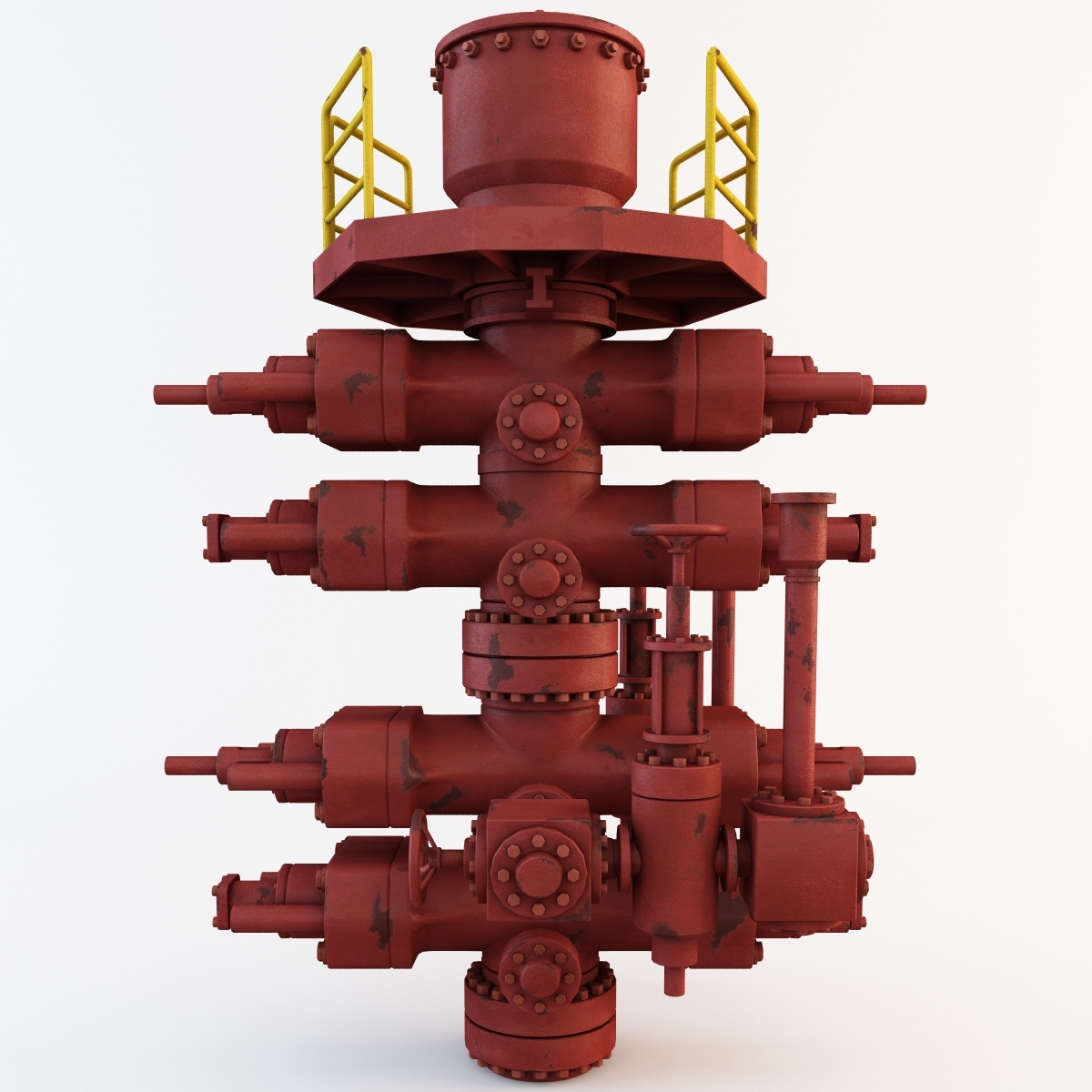

The BOP stack is the assembly of drilling-control equipment connected to the top of the casing head. The basic items of the BOP stack are blind ram preventer, pipe ram preventer, annular preventer, drilling spool, kill line, choke flowline, bell nipple, and fill line. Fig. 2.17 shows a typical BOP stack arrangement with basic equipment.

Common Surface BOP Stack Configurations BOP Products

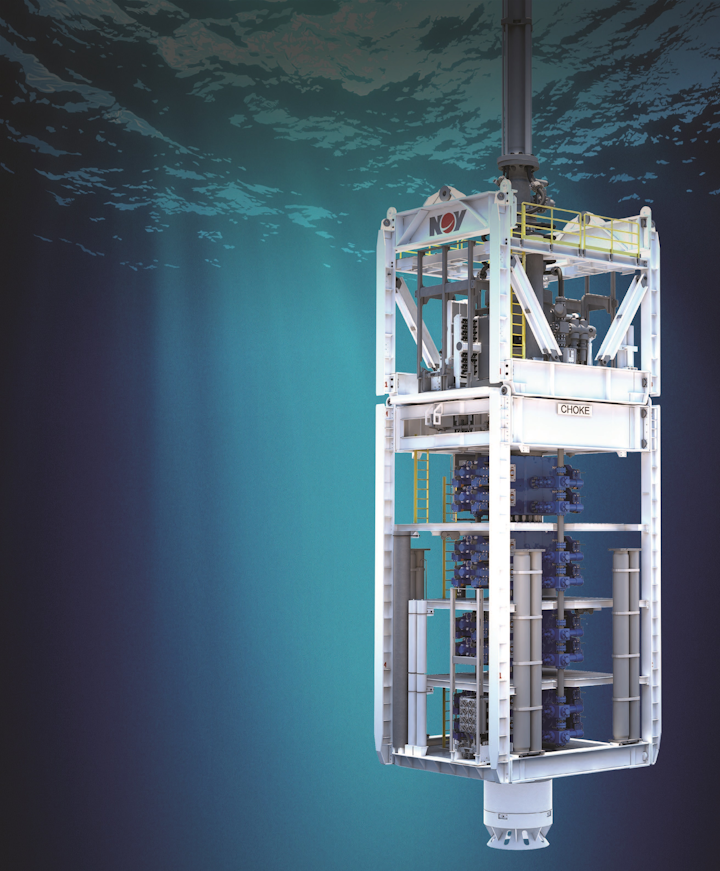

A step change in BOP history may be arriving with the qualification of National Oilwell Varco's new 20,000-psi (20K) BOP stack, two of which are set for delivery in 2021, according to a speaker at the 2020 IADC/SPE International Drilling Conference and Exhibition in Galveston, Texas, 3-5 March.

Checking the Blow Out Preventer (BOP) stack onboard the Chirag Platform

Assemblies of valves and other devices installed atop a wellhead during drilling operations are called BOP stacks; they provide a means by which rig crews are able to contain unexpected flow and high pressures.

Cameron EVO BOP stack ⋆

Offshore pressure control. From the top of the rig to the bottom of the stack, we build the most dependable blowout preventer and pressure control systems in the industry. Our 45,000-ft2 R&D facility features 13 multifunctional test bays and a hyperbaric chamber designed to simulate depths up to 15,000 ft and pressure up to 20,000 psi.

.JPG?1545393490)

BOP Stack 5 Cavity, 15,000 psi for Sale Oil & Gas Dockstr

A RAM BOP also works to prevent any unwanted materials from exploding in the system, but several are needed in the BOP stack to ensure optimum safety. RAM Valves and the BOP Stack. All the parts of a RAM BOP (and sometimes an annular BOP component) make up a BOP stack. Types can include: Blind RAMs, which close over any portion that lacks a.

.JPG?1545394865)

BOP Stack 5 Cavity, 15,000 psi for Sale Oil & Gas Dockstr

1. n. [Drilling] A set of two or more BOPs used to ensure pressure control of a well. A typical stack might consist of one to six ram-type preventers and, optionally, one or two annular-type preventers. A typical stack configuration has the ram preventers on the bottom and the annular preventers at the top.

1815M Shaffer SLX BOP Stack Triconser

Drilling & Completion. The traditional blowout preventer (BOP) stack has not experienced much change or innovation through the years. The few changes made have been in elastomers and sealing mechanism technologies. Unique innovations, however, are starting to emerge in BOP technologies. Shaffer has introduced boltless BOP doors, automated ram.

135/8" 10K BOPstack Rigfinder Oil Equipment

We recently sold two 20,000-psi (20K) blowout preventer (BOP) stacks to Transocean, making us the first oilfield equipment manufacturer to successfully design, engineer, and sell such a package. Our 20K BOP stack is designed to optimize uptime and reduce unplanned stack pulls, reaffirming the company's commitment to technical authority.

NOV sells two 20K BOP stacks to Transocean Offshore

BOP Stack Figure 2. A blowout preventer (BOP) with one annular BOP on top and two ram type BOPs are stacked together with a kill line valve and a choke line valve. A BOP installation could consist of both annular and ram-type BOPs assembled into a stack. Also, there can be a kill line valve and a choke line valve.

183/4" 15K CAMERON TL BOP STACK Triconser

Blowout Preventers (BOP) Stack is one of the rig components used to seal the wellbore and thereby contain a kick ( check drilling kick). Two main types of BOP preventers are used in the industry (both types are discussed below). This article will discuss its BOP blowout preventers stack classification, components & types.

211/4" 2K BOP Stack Triconser

A blowout preventer ( BOP) (pronounced B-O-P) [1] is a specialized valve or similar mechanical device, used to seal, control and monitor oil and gas wells to prevent blowouts, the uncontrolled release of crude oil or natural gas from a well. They are usually installed in stacks of other valves.

3d model rig bop stack

The lower assembly, referred to as the BOP stack, rests on the wellhead connector. The upper assembly, referred to as the lower marine riser package (LMRP), was placed through a remotely detachable connection on top of the BOP stack and had roughly the same gross dimensions as the BOP stack.

BOP Stacks

The BOP system must be capable of closing and sealing without losing ram closure time and sealing integrity due to the corrosiveness, volume, and abrasiveness of any fluids in the wellbore that the BOP system may encounter. Your BOP system must meet the following requirements:

What is a BOP Stack? BOP Products, Houston Texas

Blow Out Preventor (BOP) is a very important part of well control equipment and the first thing which we would like to discuss in this article is the BOP stack organization. The BOP stack can be configured in various configurations which must be suitable for the operation. API has the recommended component codes for BOP as listed below:

Cameron Type U 10K BOP Stack on transport skid with BOP lifting ring

The most common surface BOP stack configurations include using a set of two BOPs to control the pressure of oil in an oil well. A typical stack usually has between one to six stacks of ram-type preventers and sometimes one or two annular-type preventers.

135/8" BOP Stacks Cameron Type U Single, 10,000 PSI Salvex

The annular blowout preventer is installed at the top of the BOP stack (Figure WC-1) and has the capability of closing (sealing of) on anything in the bore or completely shutting of (CSO) the open hole by applying closing pressure. The sealing device of an annular blowout preventer is re-ferred to as the "packing element".