4000 Psi Concrete Concrete Mixture and 4000 Psi Concrete Mix Ratio Philippines 4000 Psi Concrete

Parts are commonly used to represent the mix ratio. A typical concrete mix ratio, for example, is 1:2:3, which equals one part cement to two parts sand to three parts aggregates. The water-to-other-ingredients ratio is also important, and it can range between 0.4 and 0.6 depending on the type of concrete and its intended use.

Concrete mix ratio Table concrete grade types Civil Sir

When it comes to concrete strength, the difference between 3000 psi and 4000 psi lies in the amount of cement used. While both mixtures have the same cement to sand ratio of 1:3:3, the 4000 psi concrete requires more cement per cubic yard. This additional cement increases the compressive strength of the concrete, making it suitable for.

The mixture ratios of concrete samples Download Table

The ideal concrete mixing ratio for any concrete is 4:2:1, where 4 parts are crushed stones, 2 parts are sand, and 1 part is cement. Note: The ratios differ according to the applications. Concrete Mixing Ratio for Slab. All types of slabs in construction require adequate strength and durability. The typical concrete mixing ratio for slabs is 1:2:4.

Concrete Mix Proportions For Different Types Of Concrete CECR

If sand was supposed too wet, he would be directed to decrease the amount of water. This was good tip however the final volume of water added to the concrete mixture was based on experience. The correct concrete mixing ratios to make a strong, strong concrete mix. Some necessary mixing ratios for concrete are 1:2:3, 1:3:3, 1:2:4.

mix ratio of concrete concrete ratio concrete mix design ratio concrete mix ratio for slab

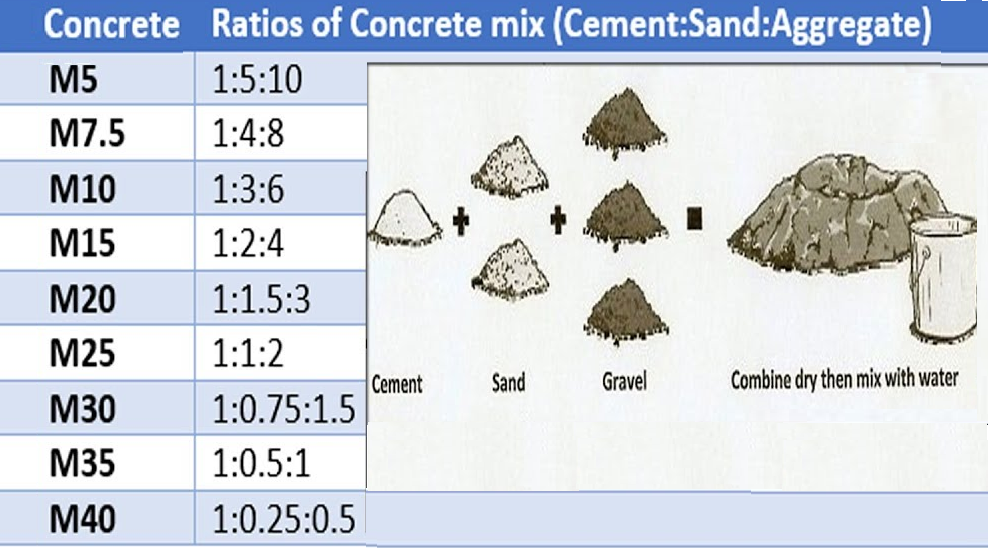

There are various grades of concrete available in the market based on these ratios. Some of them are: M10, M20, M30, M35, etc. So, what really does M10 or M20 mean or represent. "M" stands for "mix". Mix represents concrete with designated proportions of cement, sand and aggregate. And the number following "M" represents compressive.

Concrete mix ratio Various grades of concrete Concrete mix design YouTube

A concrete mix ratio is usually expressed by a set of numbers separated by colons, as is the case with a 1:2:3 ratio. This tells the mixer that they need to add 1 part cement powder, 2 parts sand, and 3 parts aggregate in order to create the desired concrete consistency.

Concrete Mix Ratio What Is Concrete Mix Ratio Types of Concrete Mix Ratio

Standard Mix Ratio for Reinforced Concrete. 1:1.5:3, Cement, Sand, and Coarse Aggregates = 1 part, 1.5 parts, 3 parts by volume. This is the standard mixture that builders use when they want to ensure the concrete has sufficient strength to resist applied loads and provide durability over time.

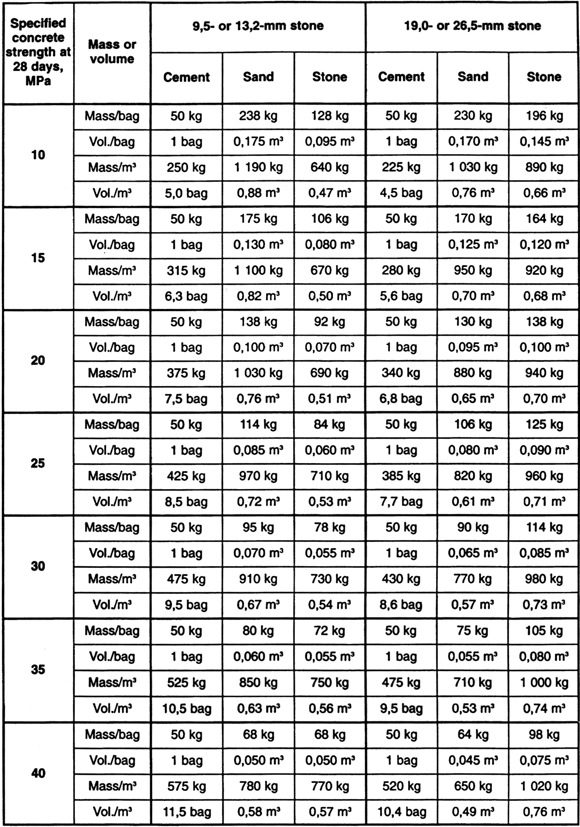

Concrete Mixes by Weight and Volume

Determine the water content, W, from required workability, size and type of aggregate. Step #4. Determine cement content, C, from W/C ratio and water content. Step #5. Estimate the density of wet fresh concrete, D, based on relative density of combined aggregate and water content.

Concrete Mix Ratio The Basics Of Cement Mix Design Orlandi

Concrete mix ratios are usually expressed as a series of numbers, such as 1:2:3 or 1:3:5. The first number represents the amount of cement, the second number represents the amount of sand, and the third number represents the number of aggregates. For example, a mix ratio of 1:2:3 means that there is one part cement, two parts sand, and three.

Concrete mix ratio Table concrete grade types Civil Sir

Introduction How to hand mix concrete so it delivers maximum strength and durability. Mixing isn't complicated and when done well, the concrete should last a lifetime. Tools Required Bucket Dust mask Hoe Rubber gloves Safety glasses Stiff bristle brush Wheelbarrow Materials Required Concrete mix

12 Concrete mix grades mostly used? Everything about concrete grades.

what are the correct CONCRETE MIXING RATIOS Updated November 19, 2023 Author: Michael Day When making your own concrete it's important to use the correct concrete mixing ratios to produce a strong, durable concrete mixture. Some basic mixing ratios for concrete are 1:2:3, 1:3:3, 1:2:4.

How To Correctly Mix Concrete? Concrete Mix Ratio DTM Mix Blog

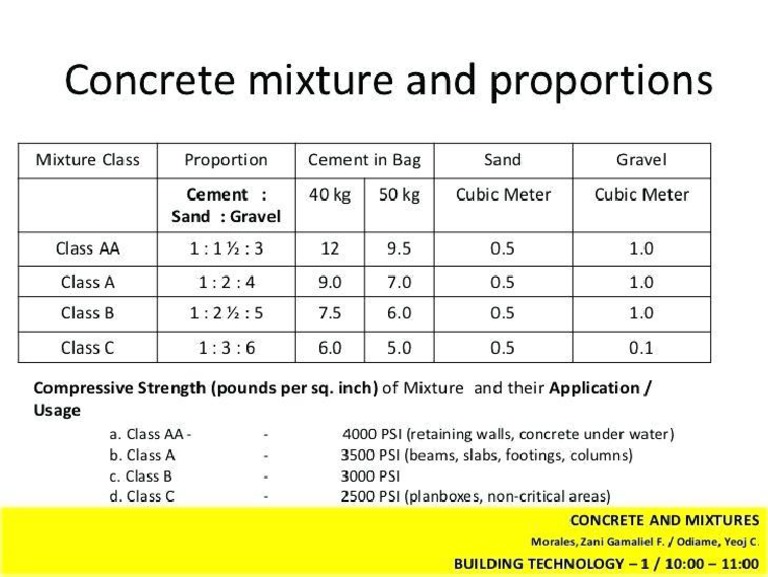

Concrete mix ratios are the proportions of concrete components such as cement, sand, aggregates and water. These mix ratios are decided based on type of construction and mix designs. However, building codes provides nominal and standard concrete mix ratios for various construction works based on experience and testing.

Mixing ratio of C20/25 concrete mixtures. Download Scientific Diagram

Concrete mix ratios are crucial for the right consistency, and the basic ingredients include aggregate, sand, cement powder, and water. Common ratios are 1-2-3 and 1-2-4, with higher sand content resulting in weaker concrete and more aggregate leading to increased strength. Concrete grades, such as M5, M10, and M15, indicate the minimum.

CEMENT MORTAR MIX RATIO AND ITS APPLICATION LCETED mixratio in 2021 Concrete mix design

Concrete Mix Ratio formula. Volume= Width x Height x Depth. Cement = Volume x 320. Sharp Sand= Volume x 600. Gravel = Volume x 1200. Water = Volume x 176. Open discussion. Use our online concrete mix ratio calculator to find the ideal mixture for your construction needs. Calculate the perfect ratio of cement, sand, aggregate, and water.

In this article, we explained how to determine the concrete mix ratio in relation to the number

40 MPa. Standard concrete. M45. Design mix. 45 MPa. 3. Design Mix Ratio For Concrete. Designed mix ratios for concrete do not have a fixed proportion of quantity for any of the materials. The materials are taken in a ratio according to the requirements of the quality & and strength of concrete.

What is the strongest concrete mix ratio?

The M25 concrete mix ratio typically consists of 1 part cement, 1.5 parts sand, and 3 parts coarse aggregate by weight or volume. This mix provides a characteristic compressive strength of approximately 25 MPa (3625 psi) at 28 days. Proper mixing and curing are essential to achieve the desired strength and durability.